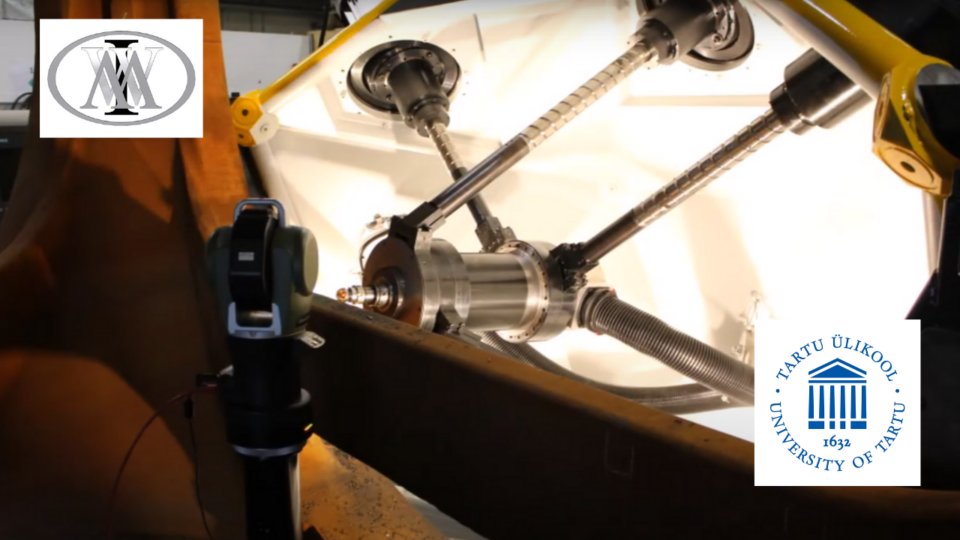

2023: Testing a robot in a production unit for the flexible insertion of large-gauge products into a machine

During the demo project, the possibility of using robots to install sheet-shaped blanks in a special device was investigated and a robotic test–workplace was implemented for placing abrasive belts on the production line. The validated robotization solution was also tested in a real production situation to automate monotonous manual work, to increase flexibility, productivity and production volumes. The novelty of the demo project consisted in the precise, fixed insertion of soft material into the corresponding narrow (5 mm) slots of the production device using an industrial robot and a special EOAT (vacuum gripper) created in this project interfaced with it. The task of servicing a machine tool of this type has not been solved in Estonia yet and no direct analogues can be found anywhere in the world. The installation of textile-based materials in the machine was successful. The installation of abrasive sheets with a paper base in the lower and upper slots of the machine tool turned out to be difficult, since the edges of the paper ends were noticeably curved upwards. An attempt was made to compensate for this by creating and validating a special trajectory for the robot’s movement. However, the large number of cyclic movements significantly reduces productivity and therefore becomes impractical. At the end of the project, ideas were collected on how to successfully solve the corresponding situation by using limiters and guides. The corresponding solution must also be interfaced with a special workbench for moving sheets. The industrial solution of the corresponding issues would remain a topic of the follow-up project. In further designing and testing the solution, an additional goal is to achieve the greatest possible flexibility in automating the process for different belts, using AI solutions.