2023: Testing AI and ML in production and business streamlining

Project title: Testing AI and ML in production and business streamlining.

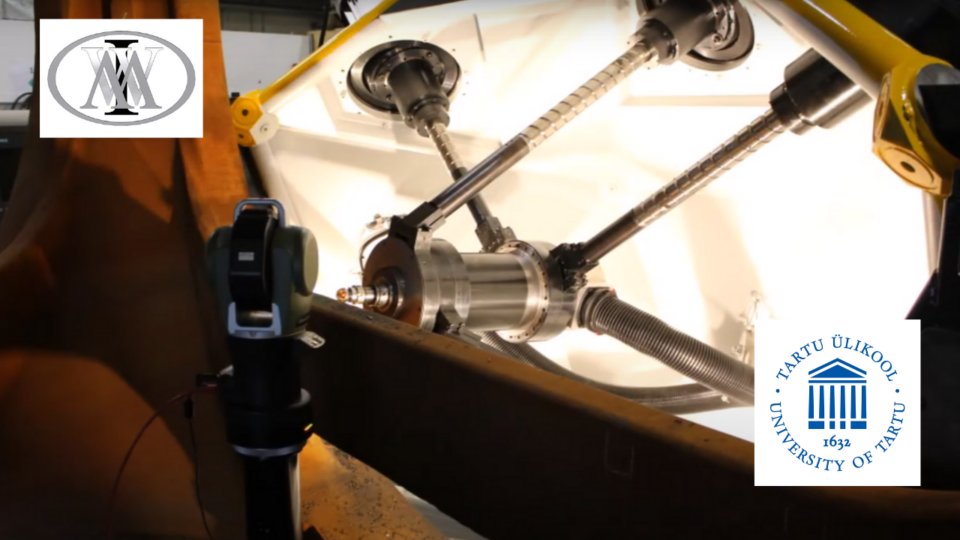

What challenge was addressed: Early integration of the creative process of the company’s production line for smart production and to take advantage of the positive opportunities of AI in the earliest possible phase of the creation of production equipment.

Aim of the project: Start monitoring the data necessary for the development of production equipment and their mutual integration patterns right at the creation stage of production equipment, which ensures the readiness of later generation equipment to receive built-in sensors. The broader goal is better productivity, maintainability, and diagnostics of the production equipment.

AI technology: A three-layer artificial neural network of the “feedforward / backpropagation” type was validated.

Project activities and results: The tangible result of the project is the ability to monitor various production parameters and record long-term history based on these parameters. Extensive testing of the production equipment took place and during this process real production data was collected on the operating parameters of the three main engines on the one hand and on the indoor climate of the production room on the other hand. The planned implementation of veneer thickness measurement has not yet been successfully achieved, and work in this field continues. A certain part of the output control with machine vision has been partially implemented, it currently works in off-line mode under another Raiku project. At present, production sorting is still performed by manual inspection. The algorithm is ready to receive both quality assessments from the machine vision system and the ERP system, to see connections beyond just the productivity and work quality of the device.