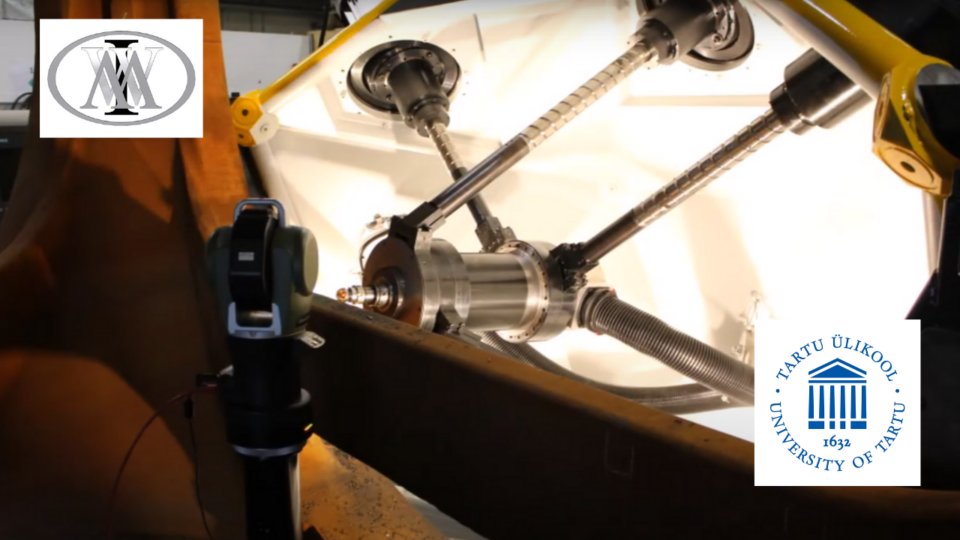

2024: Testing of artificial intelligence in the control of a bicycle tire studding machine

The goal was to propose and test a possible solution using artificial intelligence, where stud slots are detected on the tire tread and studs are installed with the correct orientation. After installing the studs, the artificial intelligence solution also performs quality control to ensure that all corresponding slots are filled and the correct orientation of the studs is ensured.

A model was validated that can be used for image recognition tasks and was suitable for identifying tire elements. The characteristics of the bicycle tire studding process and the capabilities of the studding machine were mapped. Hardware and software solutions were selected according to the requirements of the production environment. The selected artificial intelligence solution was trained and tests were carried out in the laboratory and on a real machine at the company. The artificial intelligence was trained on a production device and sample studding and tests of different tires were performed. In conclusion, it can be said that the selected hardware and software were suitable for solving the given task. The set goal of making the tire studding process faster was achieved. Thanks to the tested artificial stud solution, it was possible to identify different tires faster and the orientation of the tire tread under the camera was no longer important. The tested solution makes the tire studding process much faster and of higher quality because all stud coordinates no longer need to be taught to the device, but the artificial intelligence can generate them automatically and transmit the data to the logic controller, which interprets them into real machine movement.