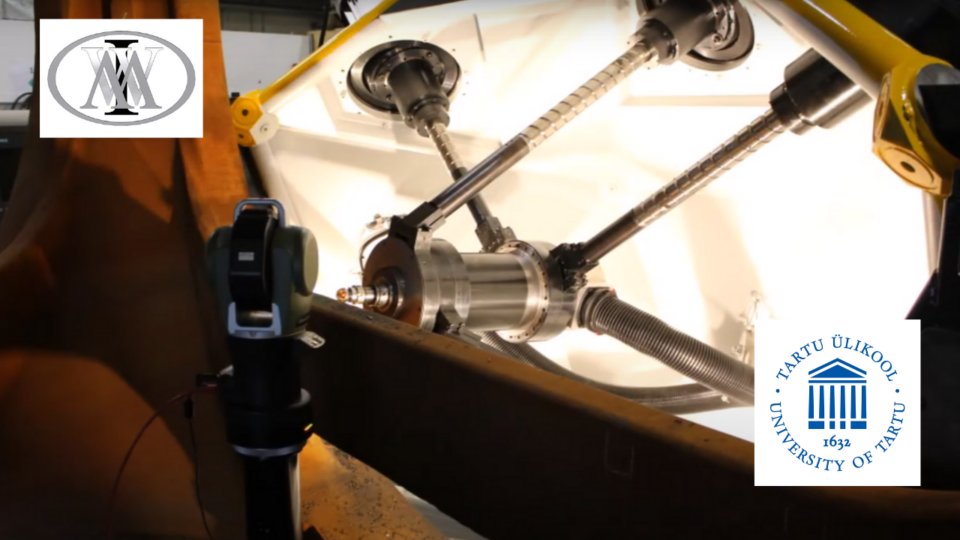

2024: Adaptive Digital Twin of custom robotics system for validation of the anomaly detection algorithms

The project aimed to address the challenge of limited real-time monitoring and safety in CNC manufacturing by testing dashboard solutions and camera-based anomaly detection. Activities focused on validating the effectiveness of real-time parameter tracking and AI-driven safety alerts. While the digital twin concept was explored, a full implementation was not achieved, and several hypotheses remain untested. The project successfully demonstrated the feasibility of certain technologies and established a scalable user interface concept, providing a strong basis for further development and future integration into manufacturing environments.