Artificial crane optimises in-house inventory and robot reduces the need for heavy manual labour

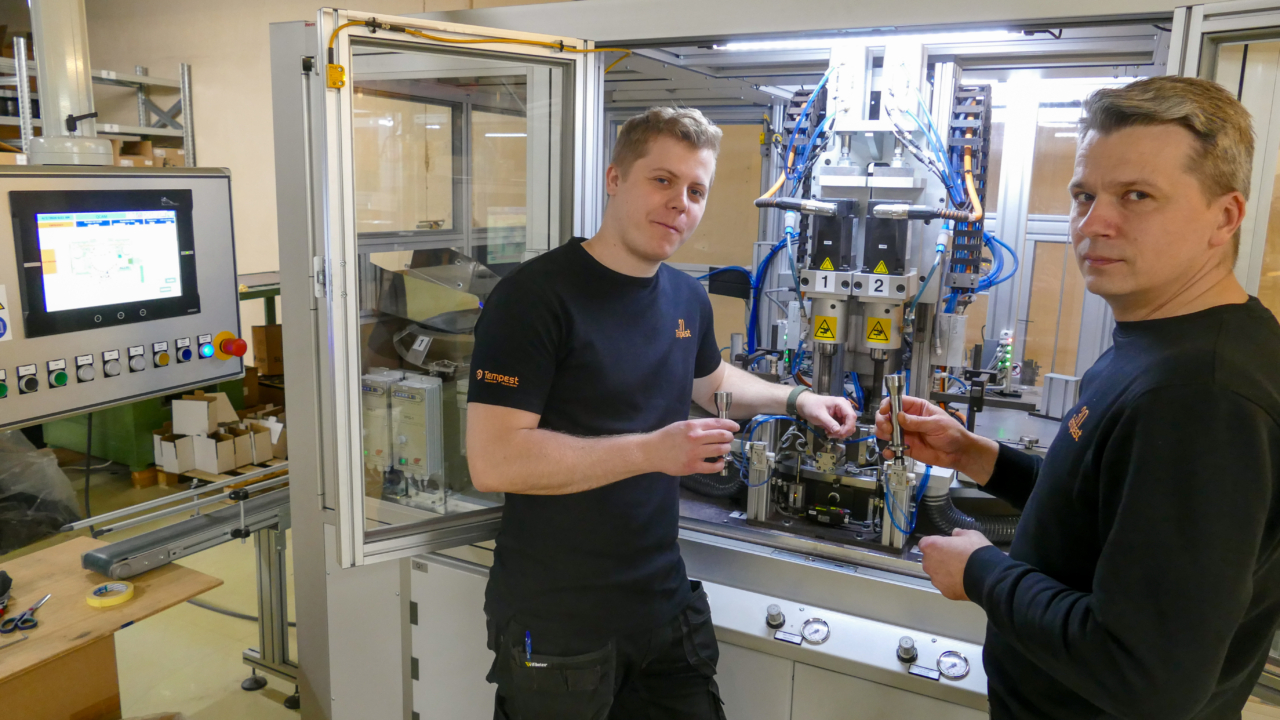

AS Tempest and the artificial intelligence and robotics centre AIRE have started to work together to increase production line capacity, automate warehouse processes and reduce manual labour through the use of artificial intelligence and collaborative robots.

The project, a collaboration between Tempest, a manufacturer and distributor of wood and metal finishing materials, and the Institute of Computer Science at the University of Tartu, aims to find out how artificial intelligence can optimise warehouse operations, reduce errors, improve inventory management and increase overall productivity in the noisy environment of an industrial company.

The project will test a system where a worker gives instructions to the AI as a voice command in Estonian and the AI sends an overview of the warehouse worker’s activities to the warehouse management software. “During warehouse processes, the artificial arm assists the human, reads the goods in motion and monitors warehouse operations. The worker can thus concentrate on his or her tasks and does not have to deal with data entry and reporting,” explains Martin Rebane, Research Projects Manager at the Institute of Computer Science, University of Tartu. The artificial arm is more flexible and adaptable in its work than conventional software or industrial robots. “On the production line, the collaborative robot assists operators like a tireless and always happy colleague,” Rebane added.

As part of the pilot project, a special collaborative robot is being developed with the help of the technology development centre OÜ IMECC. It will be interfaced with a tool that can accurately and fixedly feed unstable material – in the case of Tempest, a sheet of sandpaper 1350mm wide and 2620mm long – into the production line. There is no robotised solution for handling such a complex material in Estonia and it is a unique approach in the world,” said Tempest’s Lichettey Aavik.

The solution was designed and tested with flexibility in production automation in mind. The project will improve the working conditions in the companies and reduce physically demanding and routine tasks. The project will allow the impact of the new technology on production operations to be assessed before it is implemented throughout the company.