2023: Testing AI-Based Quality Assurance System for Enhancing Coordinate Measuring Machines with Machine Vision

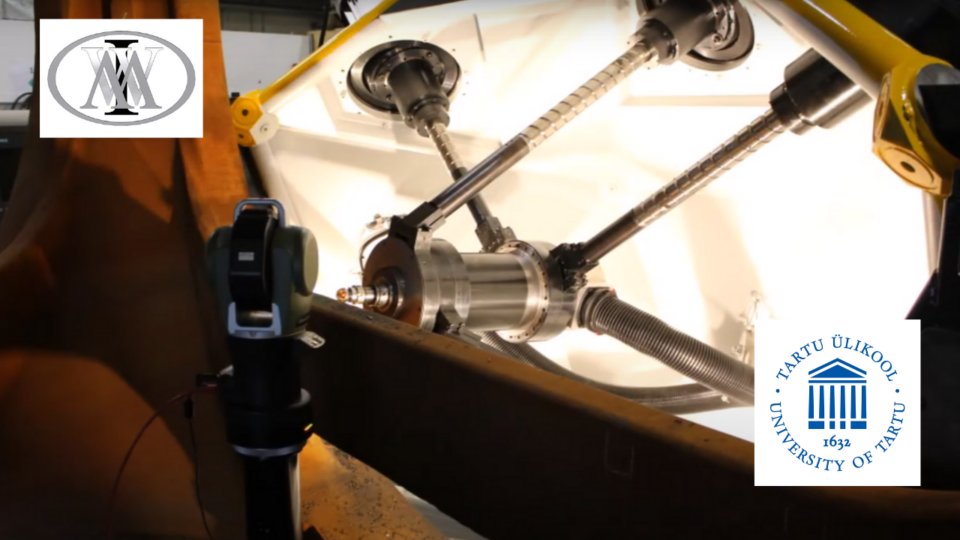

This project addressed a critical challenge faced by small and medium-sized manufacturers operating in high-mix, low-volume environments, where traditional quality control methods require time-consuming setup of custom fixtures for each unique part. The aim was to validate an AI-powered system that enables coordinate measuring machines (CMM) to automatically identify parts and their positions, eliminating the need for manual fixture setup and reducing quality control duration. Two AI approaches were validated: a computer vision-based solution using the Find Object ROS package, and a deep learning solution utilizing Deep Object Pose Estimation (DOPE). The project successfully demonstrated that both approaches could automate part recognition and measurement program selection, with the vision-based solution offering quick setup but environment sensitivity, while the deep learning approach provided more robust detection but required longer training. The resulting system shows significant potential for revolutionizing quality control processes in flexible manufacturing environments, though further optimization is needed for streamlining the introduction of new parts to the system.