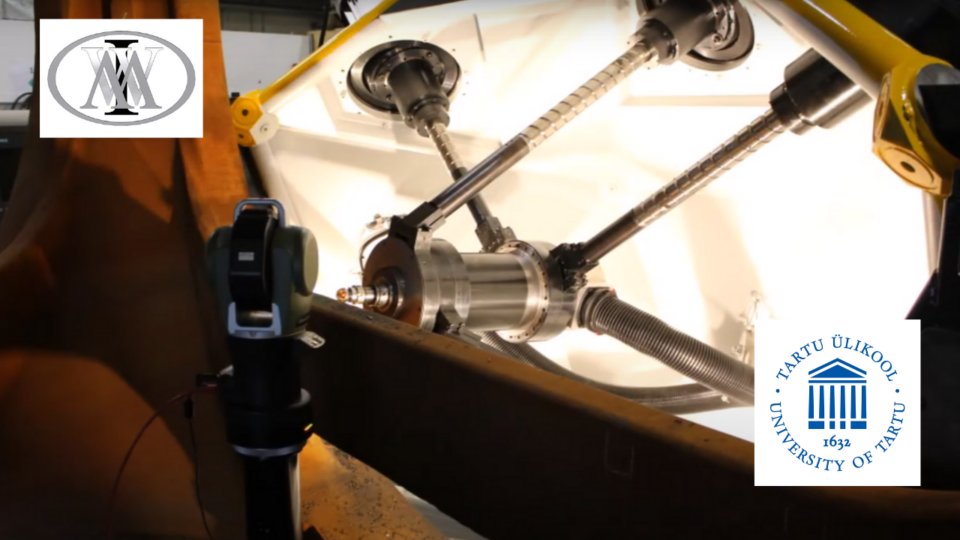

2023: Testing a production robot solution for placing parts on a measuring table with a robot manipulator

This project focuses on testing an AI-enhanced robotic system for automating the handling and measurement of machined parts using a coordinate measuring machine. A robotic arm, interfaced with a vision system, detects and grips parts, placing them on the CMM for inspection. The system utilizes the Robot Operating System ROS and MoveIt for motion planning and communication, ensuring precise and optimized handling. Artificial intelligence is incorporated to enhance object recognition and adaptive path planning, improving system efficiency and reliability. By adapting AI-driven automation with industrial measurement processes, this solution aims to optimize quality control in manufacturing, reduce human intervention, and enhance overall production efficiency. The approach has potential applications in CNC machine tending, automated inspection, and Industry 4.0-driven smart manufacturing environments.