2024: Testing of a robotic assembly workstation for the production of acoustic panels at Silen OÜ

One of the challenges that this demonstration project sought to solve was the robotic production of acoustic panels to reduce the time needed to manufacture these.

The demonstration project tested the robotic screwing process for acoustic panels of different configurations, taking into account the different dimensions of the panels, the number of screws to be installed and their installation.

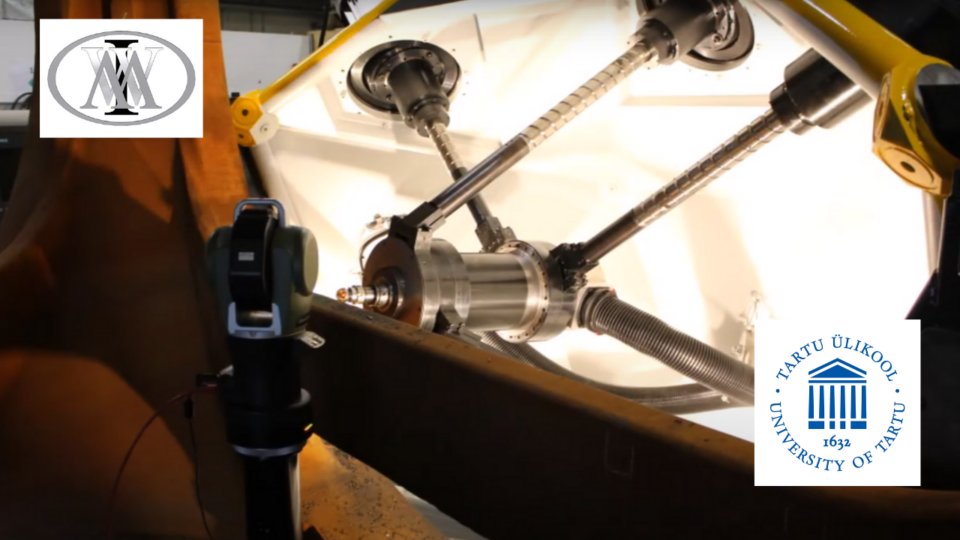

This demonstration project linked robotics (UR10 collaborative robot), automation (screw feeder, automatic screwdriver, intelligent jig), AI tools (digital twin workstation, machine vision tools, simulation of robot work trajectory).

The solution took into account the company’s specific production processes and the requirements for acoustic panel parameters, as well as the possibilities for implementing fully automated production in the company or for deployment in other companies in the sector.

Results of the demonstration project: realization of the product assembly operation, adjustment of the assembly cell concept, selection of a suitable robot for the assembly operation, selection of the tools, simulation and testing, data collection, analysis and verification of the results.