2023: Testing of novel AI based intelligent robotic assembly workplace for the production of bag filters in Vado Filters OÜ

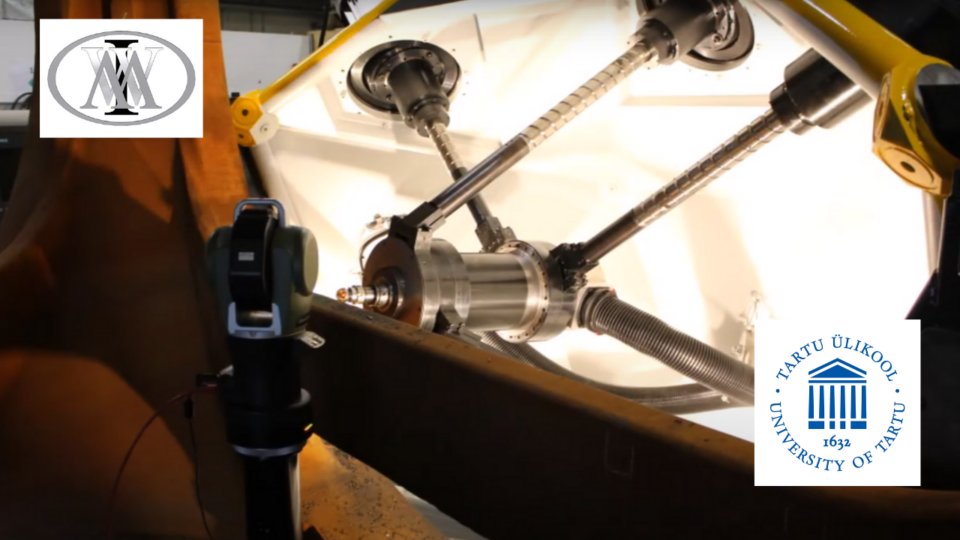

The purpose of adjusting an intelligent workplace for robotic assembly of bag filters is to reduce the proportion of monotonous hand work, with reduction of workers’ fatigue and possible errors.

The increase of efficiency is a key factor of today’s production. Therefore, it is important to speed up the assembly process and reduce the non-productive time in the production process. Thereby, the high quality of the product has to be achieved.

The novelty of the project lies in the validation and testing of a prototype of an intelligent and flexible robotic assembly system to handle textile materials that do not hold form.

As a result of the project, a physical prototype of the robotic system with the principles of intelligent assembly has been validated. In addition to engineering solutions, a variety of AI technologies have been used – machine vision to ensure the quality of the assembly process and to optimize the production process by data analysis.