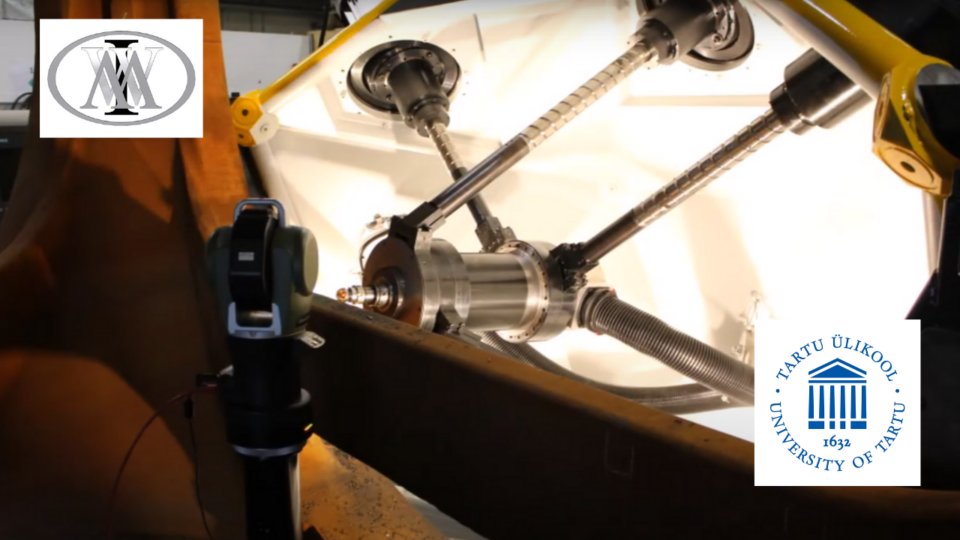

2023: Validating applicability of an artificial intelligence-based optimization model for production processes based on Scandinor OÜ new planned production unit

Project title: Validating Applicability of AI-based Optimization Model for Production Processes in Scandinor OÜ’s New Manufacturing Unit. Challenge Addressed: Enhance production throughput, reduce bottlenecks, and optimize production processes using AI technology. Project Aim: To optimize production processes, increase throughput capacity, reduce costs, and improve product quality. AI technology was validated through simulation and real-time data analysis. Project Activities and Results: Validated a virtual model of production processes, implemented AI-based optimization models, and integrated with DIMUSA MES system. Results: ~15% increase in production throughput, ~10% reduction in production costs, ~20% reduction in defects, improved production quality and flexibility.