In February three demo projects were launched in the amount of 180,000 euros.

In February, approval was granted for 3 new AIRE demo projects.

Juhan-Madis Pukk, a member of the AIRE advisory board, said that the AIRE demo project service allows manufacturing companies to test artificial intelligence and robotics technologies in collaboration with university researchers before making investments. It also encourages companies to make further investments in digital technologies.

Supported demo projects:

Based on the idea competition, the AIRE team offers support to selected demo projects that utilize artificial intelligence and related technologies (including robotics), aiming to bring universities closer to industry. Companies can implement novel solutions not found in the private market, whether it’s testing new technology or software, data analysis methods, cloud solutions, preventive maintenance, or developing digital twins. Additionally, the advisory board members of AIRE provide expert advice to companies for project implementation.

In this round, advisory board members providing guidance to teams included: Sirli Männiksaar (CEO of Ericsson Estonia), Juhan-Madis Pukk (FlowIT), Marily Hendrikson (Ministry of Economic Affairs and Communications), Martin Goroško (committee member and head of private capital advisory service).

ASG Robotics OÜ – received funding of 60,000 euros.

Demo project title: “ Digital twin for validation of AI-based motion planning and control for robot-assisted processing of curved surfaces.” Project manager: Karl Kruusamäe, University of Tartu.

ASG Robotics is a leading developer and manufacturer of automated production systems with a 30-year history. The company’s technical director, Alexander Gadalov, stated during the presentation of the demo project that there are many areas in production that are difficult to automate or where the cost of automation is extremely high for small and medium-sized manufacturing companies.

“One such problem is processing materials with robot manipulators, where the object has a complex and potentially changing shape. For example, the object has curved surfaces, and the robot’s end-effector tool must precisely follow this curved surface to perform the cutting task,” explained Gadalov.

The aim of this project is to develop a digital twin for processing curved surfaces with a robot. The digital twin will then be used to test, validate, and compare motion planning algorithms to achieve precise movement of the end-effector along any predefined path along the curved surface and ensure collision-free movement.

Aktaprint OÜ – received funding of 60,000 euros.

Demo project title: “ Validation of a prototype of a software robot for automatic modelling, planning and optimiztion of production processes based on artificial intelligence in Aktaprint OÜ.” Project manager: Tarmo Kadak, TalTech.

Aktaprint, founded in 2000, is an offset printing company producing high-quality printed products with versatile finishing options. According to the company’s CEO, Urmas Savi, solving the module described in the project is a key issue for streamlining processes. The aim is to create and validate a prototype software robot designed to model and optimize various products and production processes of the company as efficiently as possible.

“The task of the robot is to find a sufficiently good production process for a specific product or order throughout the entire order fulfillment period. Starting from the customer’s desire to purchase (including filling out the pricing form on the website’s customer interface), through order requirements, and ending with the production of finished products that meet those requirements,” described Savi the goal.

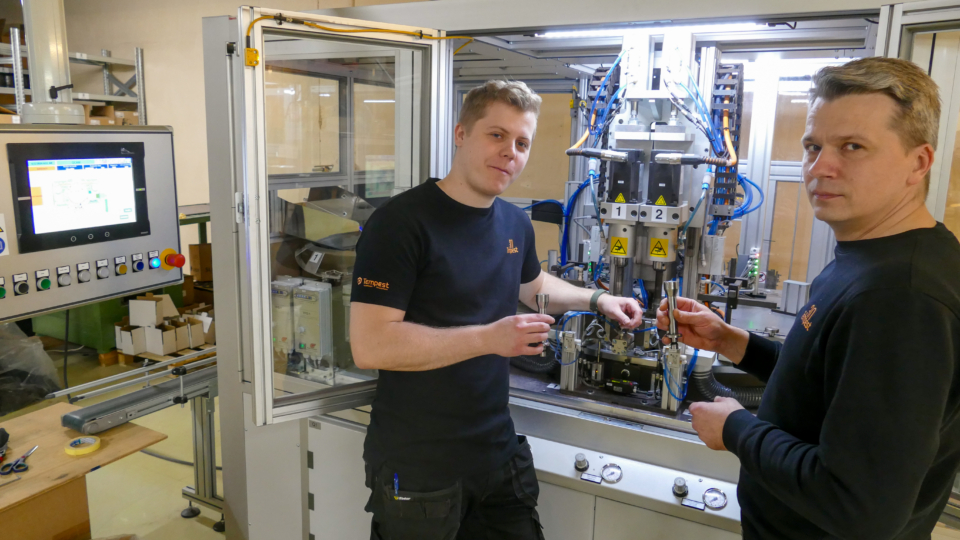

AGES Partner OÜ – received funding of 60,000 euros.

Demo project title: “Testing of automation of 2D scanning of products – detecting shadow line.” Project manager: Alar Niidas, TalTech.

AGES Partner OÜ designs and manufactures durable and high-quality custom transport case solutions and foam interiors (Ages Case). They are a growing company that invests in regular automation and digitization every year. In this project, a concept and prototype for a device to measure the shadow lines of real 3D objects will be created, and testing will be carried out in a test environment. The system will be used to produce the most suitable transport packaging for these objects, ensuring their safe packaging.

Currently, the production process involves too much manual work, and the level of automation needs improvement. The system being developed will reduce the amount of manual labor and improve work quality (avoiding errors and increasing precision).

Good to know:

In the previous season, 17 demo projects were launched in collaboration between companies and researchers. The idea competition is open year-round, with projects launched 3-4 times a year.

New applications (along with CVs and other attachments) can be sent to demonstration-projects@aire-edih.eu.

For more information about demo project services and ongoing projects, visit: https://aire-edih.eu/service/demo-projects/